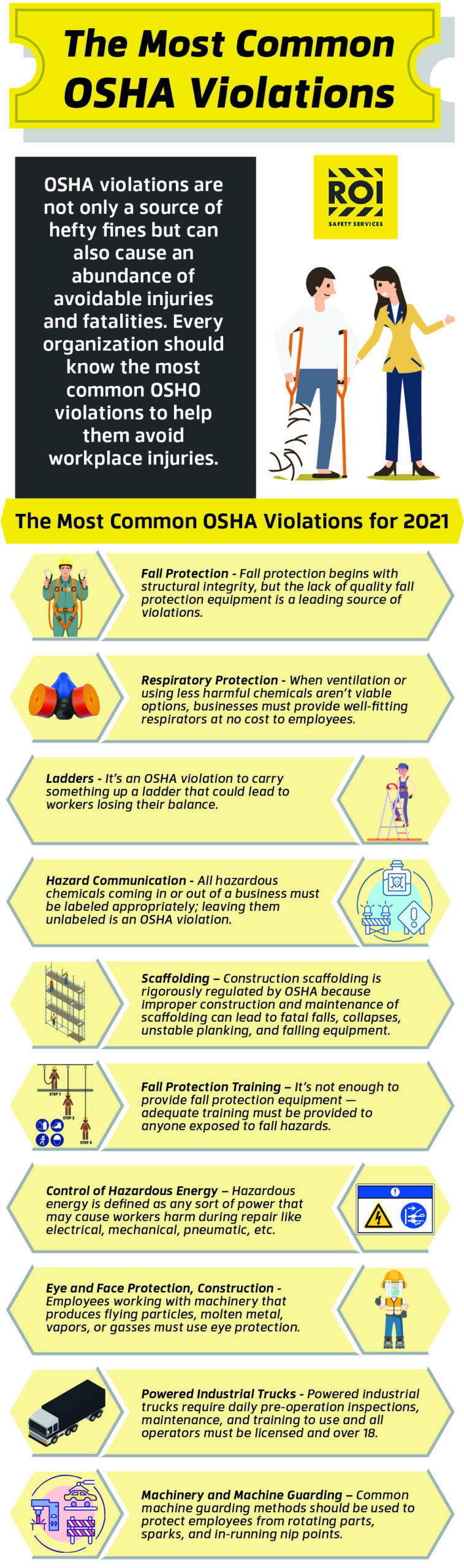

OSHA violations plague every industry. They’re not only sources of hefty fines but also cause for an abundance of avoidable injuries and fatalities. In 2020 alone, the Board of Labor Statistics reported 2.7 million nonfatal workplace injuries.

To help companies reduce violations and make their workplaces safer, OSHA publishes the 10 most common violations every year. Understanding these common hazards is the first step in combatting workplace injuries. Combining that knowledge with proper OSHA training makes for a safe, efficient workplace.

1. Fall Protection

Fall protection begins with structural integrity, but the lack of usable fall protection equipment is a leading source for violations. This includes:

- Guard rails

- Safety nets

- Harnesses

- Covers on holes

In general, one or more of these safeguards should be in place if a worker is six feet or more above the next level. That may not sound very high, but injuries from falls between six and 10 feet account for 28% of all fall-related fatalities.

2. Hazard Communication

For workers to use the right equipment and precautions around hazardous materials, they must know what they’re dealing with. Even if chemicals are stored in the proper containers, leaving them unlabeled is an OSHA violation.

All hazardous chemicals coming in or out of a business must be labeled appropriately. This includes providing accessible data sheets and training so workers know what signs mean and what procedures to adhere to.

3. Respiratory Protection

When ventilation and substituting less harmful chemicals aren’t viable options, businesses must provide well-fitting respirators at no cost to employees.

Respirators must also be stored properly to avoid damage, maintained, and disposed of when they’re no longer in working order. Their use should be outlined in a written plan and training. Not having any one of those pieces in place constitutes an OSHA violation.

4. Scaffolding

Construction scaffolding is rigorously regulated by OSHA because improper construction and maintenance lead to fatal falls, collapses, unstable planking, falling equipment, and contact with power lines. To prevent those hazards, every part of scaffolding must adhere to certain guidelines:

- Every component must support at least 4 times the maximum intended load.

- All suspension ropes and connecting hardware have to be capable of holding six times the intended load.

- Each walkway must be 18 inches wide in most scenarios.

While OSHA scaffolding standards get more complex than that, scaffolding violations largely include using damaged scaffolding, obstructed walkways, and having no guardrails on sections that require them.

5. Ladders

Ladders are simple equipment, but 300 people die from ladder-related injuries every year. Even more are treated for injuries, costing businesses $24 billion annually. Violations stem from ladders placed around obstructions, broken rungs, and improper setup, such as there being too much space between the foot of a ladder and a wall.

With ladder violation fines reaching up to $13,000 per day, OSHA takes ladder usage very seriously. In addition to risks posed by damaged ladders, it’s an OSHA violation to carry something up a ladder that could lead to a worker losing their balance.

6. Control of Hazardous Energy

Hazard energy is defined as any sort of power that may cause workers harm during repair. This includes electrical, mechanical, pneumatic, and chemically-powered engines and devices. Control of hazardous energy violations only extend to repair and maintenance, not regular use.

When repair crews work on equipment, there must be a lock affixed to the device so it doesn’t start accidentally. Failure to do so results in a violation. Like ladder violations, hazardous energy violations reach up to about $13,000 per day.

There must also be a tagout, or a label that informs other workers why the machine is locked out and by whom.

7. Powered Industrial Trucks

Also known as forklifts, powered industrial trucks require daily pre-operation inspections, maintenance, and training to use. Under federal law, all operators must be licensed and over 18.

Forklift violations range from not providing training refreshers to unsafe operations. As defined by OSHA, unsafe use means driving a forklift too fast, with an elevated load, or too close to platform and dock edges. Forklift modifications must not affect safety or capacity and must always meet manufacturer approval.

8. Fall Protection Training

This OSHA violation category bolsters regulations regarding scaffolding, ladders, and fall protection. It’s not enough to provide fall protection equipment — adequate training must also be provided to anyone who might be exposed to fall hazards.

Training must include equipment use, setup, limitations, and the roles of employees in safety monitoring systems. Certification must include the employee’s and instructor’s names, training dates, and the employer’s signature. When old equipment becomes obsolete or an employee demonstrates inadequate fall protection knowledge, employers must provide refresher training.

9. Eye and Face Protection

Eye and face protection violations result from not using adequate eye protection or not using it all. Employees working with machinery that produces flying particles, molten metal, vapors, or gasses must use eye protection. This includes welders, wood product manufacturers, and some waste technicians.

Along with being durable enough for its purpose, eye protection must be comfortable to encourage use, fit snuggly and be able to be cleaned. It must also extend to the side of the eyes. Not meeting all of these requirements results in thousands of dollars of daily fines.

10. Machinery and Machine Guarding

While hazardous energy control extends only to maintenance, machine guarding is for regular operation. Affixed to machines themselves, common machine guarding methods include barrier guards, electronic safety devices, switches, two-handed control devices, and automated ejection systems. These are to protect employees from rotating parts, sparks, and ingoing nip points.

Guards must also not create hazards and ideally allow for lubrication when in place. Most commonly, they’re needed for shears, presses, saws, milling machines, and rotating drums.

Prevent OSHA Violations With Proper Training

From general hazard assessment and equipment usage to the particulars of every OSHA regulation, OSHA training prevents workplace injuries by keeping employees informed. Whether your business requires online training or on-site demonstrations, let ROI Safety Services of California be a part of your safety plan. Contact us today for a quote and to minimize your business’s OSHA violations and safety hazards.